TC burrs - INOX cut

With the INOX cut, PFERD has developed innovative burrs for work on stainless steel (INOX). The INOX cut is characterized by an extremely high stock removal rate on all austenitic as well as rustand acid-resistant steels. It creates significantly less vibration than a comparable cross cut.

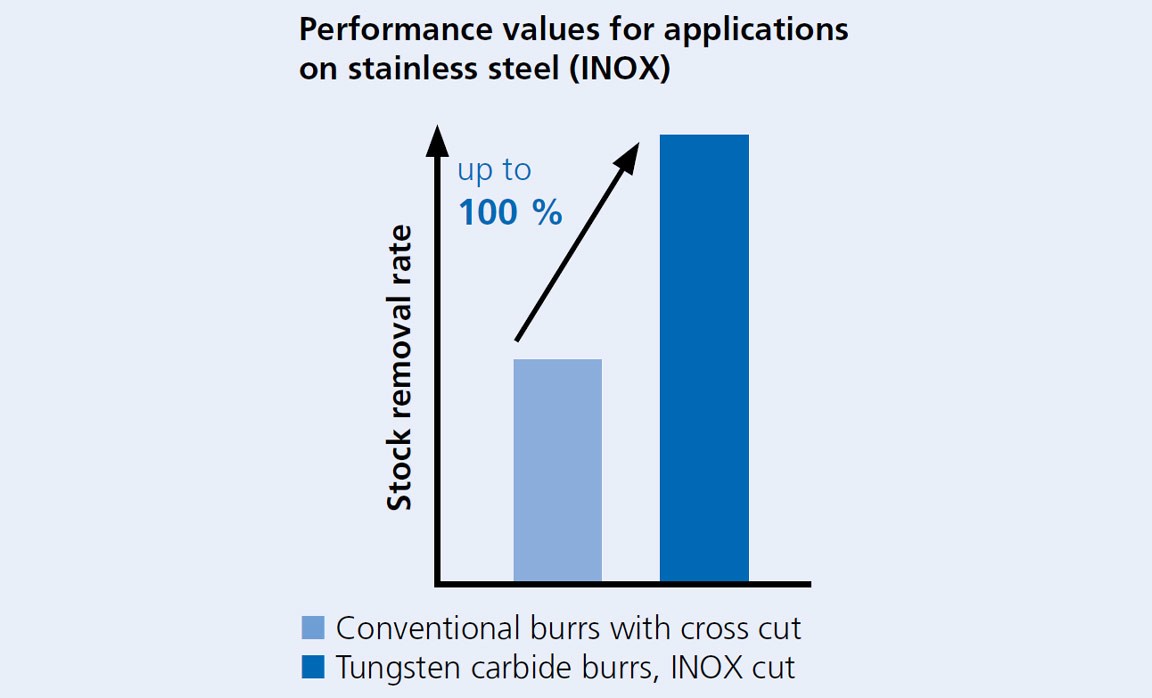

In addition, compared to conventional cross-cut burrs, the INOX cut features a 100 % higher stock removal rate when used on stainless steel.

Advantages:

- Outstanding stock removal rate and tool life due to the innovative tooth geometry.

- Achieves high surface qualities through optimum chip formation.

- Prevents heat discolouration in the material due to the reduced heat generation.

- Reduced wear on the tool drive due to impact-free work without chatter marks, thanks to the high concentricity.

Materials that can be worked:

- Stainless steel (INOX)

- Soft titanium alloys (tensile strength < 500 N/mm²)

Applications:

- Milling out

- Levelling

- Deburring

- Cutting out holes

- Surface work

- Work on weld seams

Matching tool drives:

- Flexible shaft drive

- Straight grinder

- Robot

- Machine tools

Recommendations for use:

- If possible, use the tools on powerful drives with elastically mounted spindles to avoid vibration.

- For the cost-effective use of burrs, work with higher rotational/cutting speeds.

- Power recommendation for tool drives:

- Shank diameter of 3 mm: 75 to 300 watts

- Shank diameter of 6 mm: from 300 watts

- Please observe the rotational speed recommendations. The RPMs shown in the product tables on the product pages are for work on stainless steel (INOX) only.

Safety note:

The very high stock removal rate can cause discolouration on the shank. This does not constitute a safety risk.