Steel: a material with a history and a future

Steel is a material that boasts outstanding properties and possibilities, which no other material can claim in the same combination. Indeed, the intensive – and as yet, inconclusive – search for alternative materials with similar properties is further proof of the potential that this material with its long history still has to offer.

We have compiled our many years of experience and our up-to-date expertise in specific stock removal and performance characteristics for work on steel, particularly construction steel, carbon steel, tool steel, case-hardened steel and other non-alloyed steels in this article.

Steel: an overview

The history of steel dates all the way back to 2000 B.C. There were the first signs of simple non-ferrous materials even back then. In ancient times and in the Middle Ages, iron ore was smelted at very high temperatures without melting, using shaft furnaces.

In the 14th Century A.D., the first charcoal-fired blast furnaces were developed in Europe. With this new invention, smiths were able to melt iron. However, the cast iron that they produced was brittle and could not be forged, due to its high carbon content.

In 1784, Henry Cort developed the puddling process. Now, the molten pig iron was brought into contact with air by manually stirring it to remove components such as carbon, sulphur or phosphorous from the material. The process enabled the production of a forgeable and elastic type of crude steel, also known as wrought iron.

In the 19th Century, steel became even more important. As the invention of the steam engine enabled companies to transport increasingly heavy loads, coal mining provided the coke required for steel manufacturing.

What types of steel are there?

Construction steels make up the largest group of steels. They are also called common construction steel, ordinary steel or structural steel. This group constitutes over 90% of all steel production. It also includes unalloyed construction steels and fine-grained and weatherproof construction steels.

Corrosion-resistant stainless steels (INOX) are sometimes also counted as construction steels, as they can be used to make similar constructions to the types of steel named above.

What types of processing does construction steel offer?

Steel also stands out because it can not only be processed using machines, but also using manually operated tools, and can therefore be used outside factories in the construction of buildings, vehicles, containers, plants and much more. There are many different ways to process steel:

- Forming: Bending, compressive forming, tensile forming and tensile-compressive forming

- Cutting: Cut-off grinding, sawing, cutting, flame and plasma arc cutting

- Machining: Drilling, turning, milling, grinding, filing

- Joining: Welding, screwing, riveting

- Processing surfaces: Grinding, polishing, brushing, embossing, engraving, laser inscription

- Treating surfaces: Coating, painting

- Changing property: Annealing, heat treatment

What is construction steel used for?

Construction steels are commercially available as units of sheet metal, bars, profiles and tubes. They may have been hot or cold rolled or hot or cold drawn. Due to its material properties and the ease of processing and welding steel, it can be used in many different sectors, e.g.:

- Steel construction and metalworking shops

- Machine and plant construction

- Fitting and container construction

- Architecture and construction

- Dockyards and offshore technology

- Vehicle construction

- Pipeline construction

Why is construction steel used in so many sectors?

Their yield points, malleability, suitability for welding and machinabilty are decisive reasons to use construction steels. The most widely sold steel is general or unalloyed construction steel. This is because:

- Its properties are suitable for the most common applications.

- It is affordable.

- It has good properties for processing and welding.

- There is a large selection of alloy variants, so whichever machining properties are desired on an individual basis, the right type can be found.

- A wide selection of semi-finished products is available, most of which are standardized.

Outlook

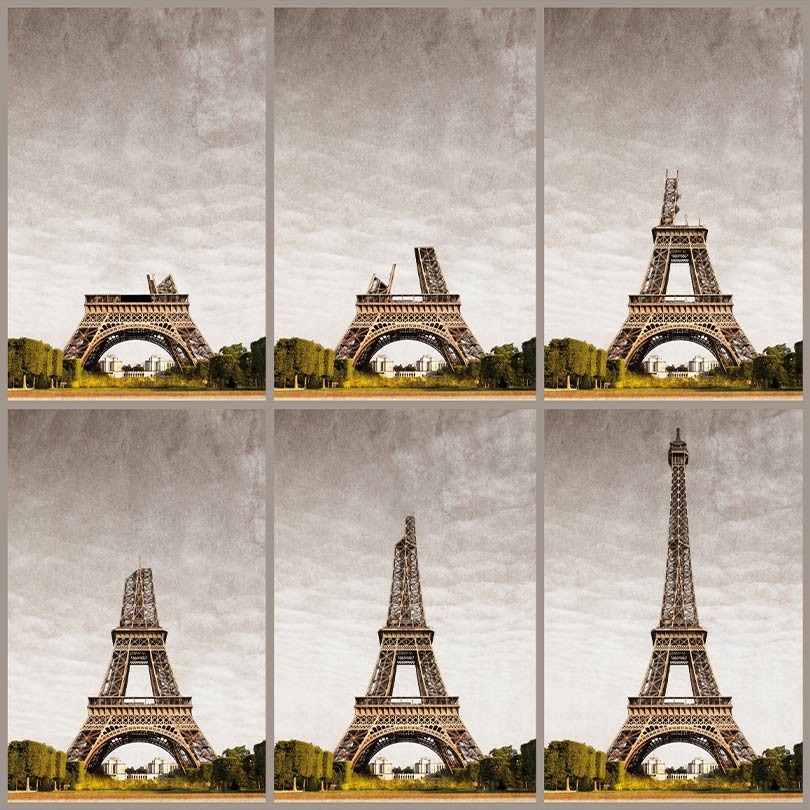

Since the Eiffel Tower was erected as part of the Exposition Universelle in 1889, steel production has increased continually. Production processes have continued to develop over the years. As a result, there are now over 2,500 standardized types of steel, which are in use in the widest range of areas. With all that in mind, steel has clearly set itself apart from its older relative, iron.

From an environmental viewpoint, steel is excellent, as it can be recycled an almost unlimited number of times without a loss of quality. After use, the scrap metal can be collected (according to type), melted down, and processed into new material