Saw chain: the most important basics

What is the basic structure of a saw chain?

The saw chain of a chain saw is a circumferential chain, which is why it is also called an "endless chain". The chain is comprised of repeated chain links which are joined to each other so they can move. The chain length is determined by the number of drive links.

What are the components of a saw chain?

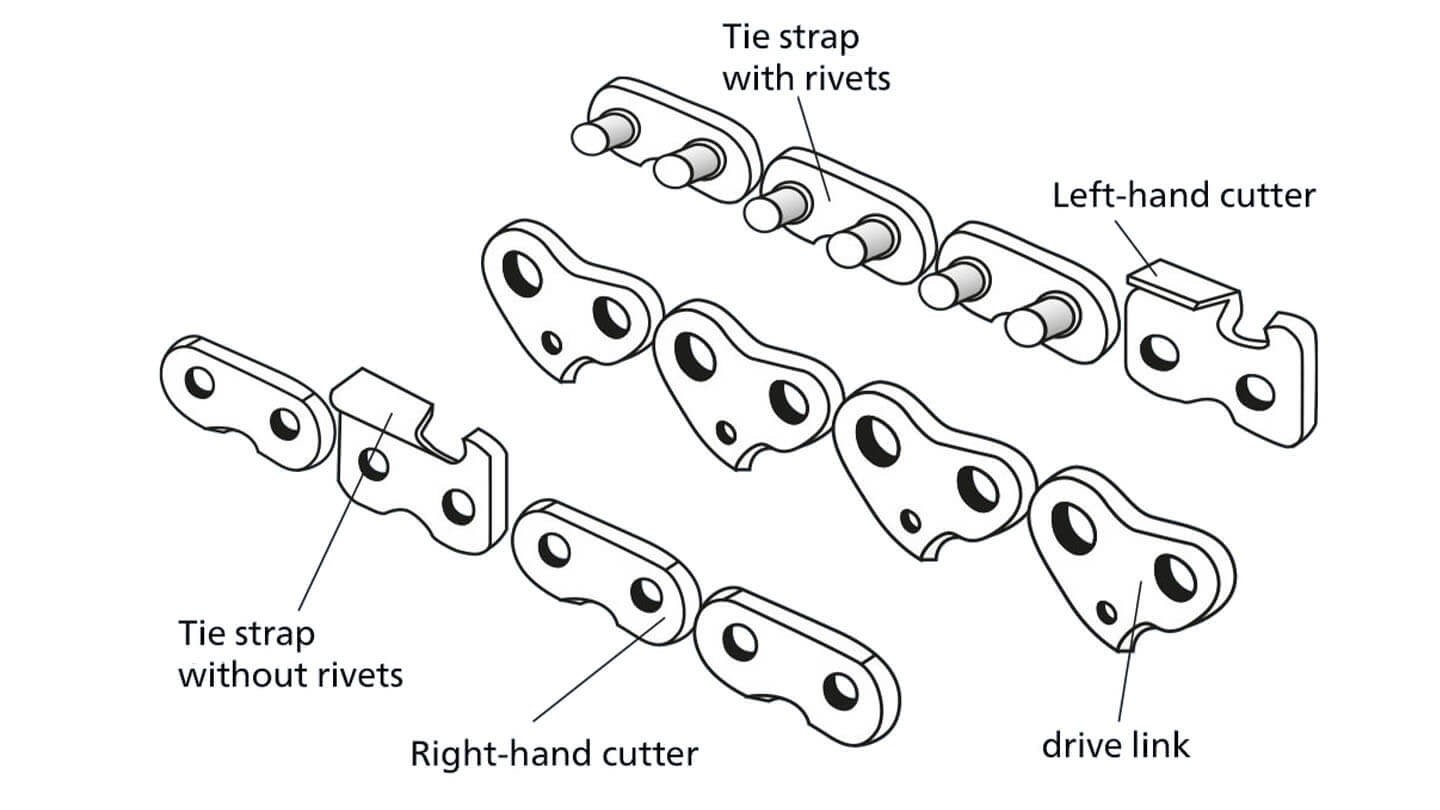

A saw chain is comprised of cutting links, drive links and tie straps.

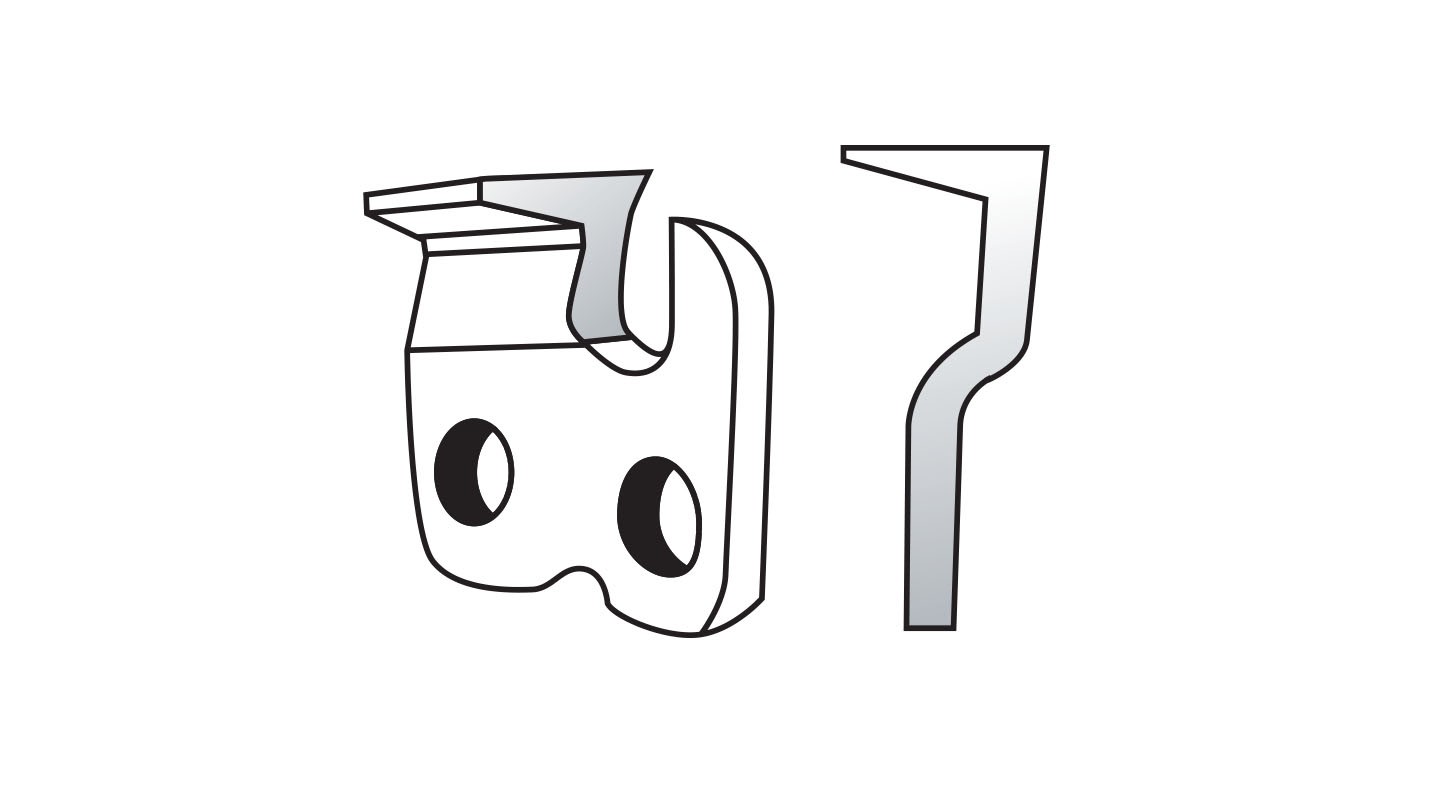

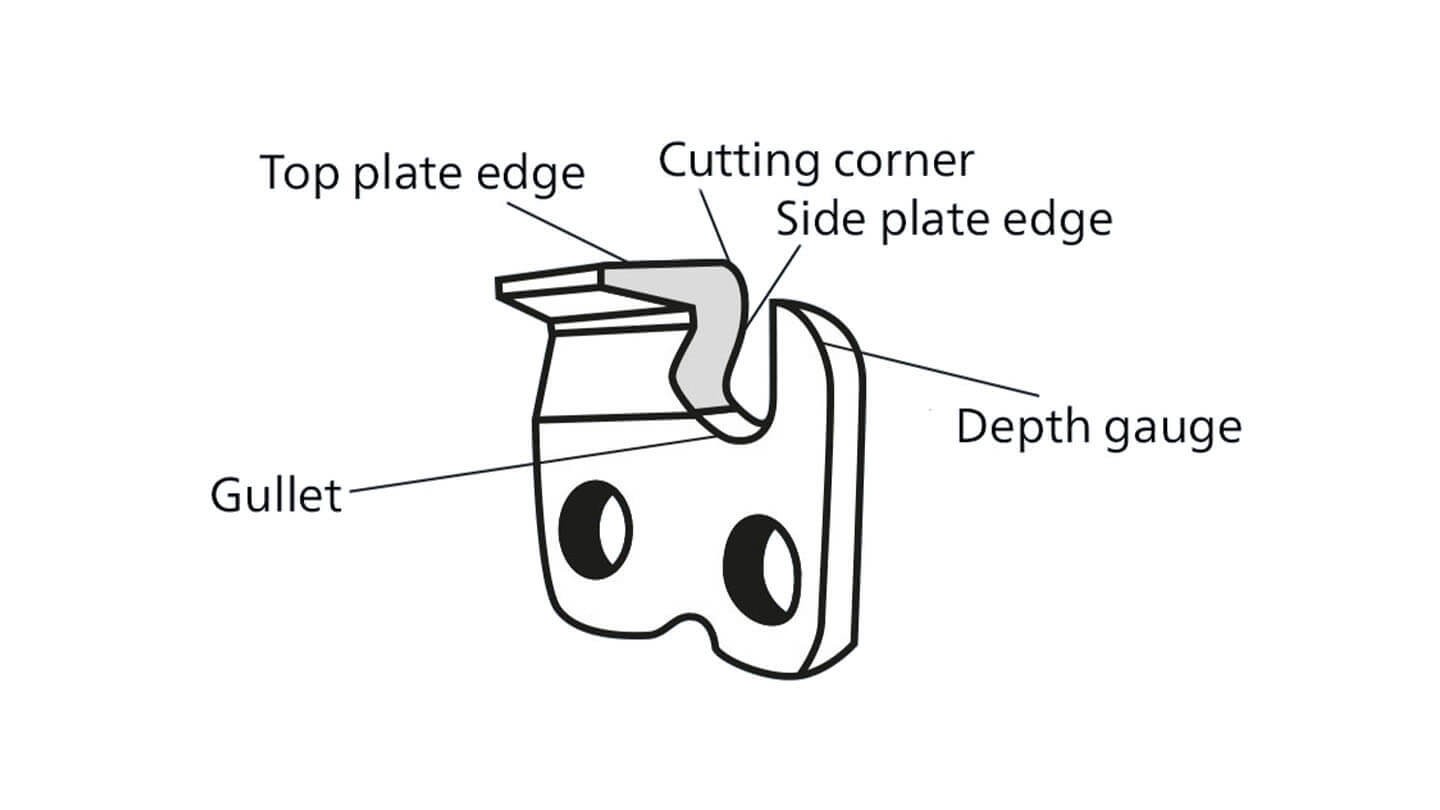

Top plate, tooth base, cutting corner and side plate edge, as well as depth gauge form the cutting link. The cutting corner of the tooth carves out the wood chip and the side plate edge cuts this off the side of the material. The distance between the depth gauge and the cutting corner regulates how far the plane tooth penetrates into the material.

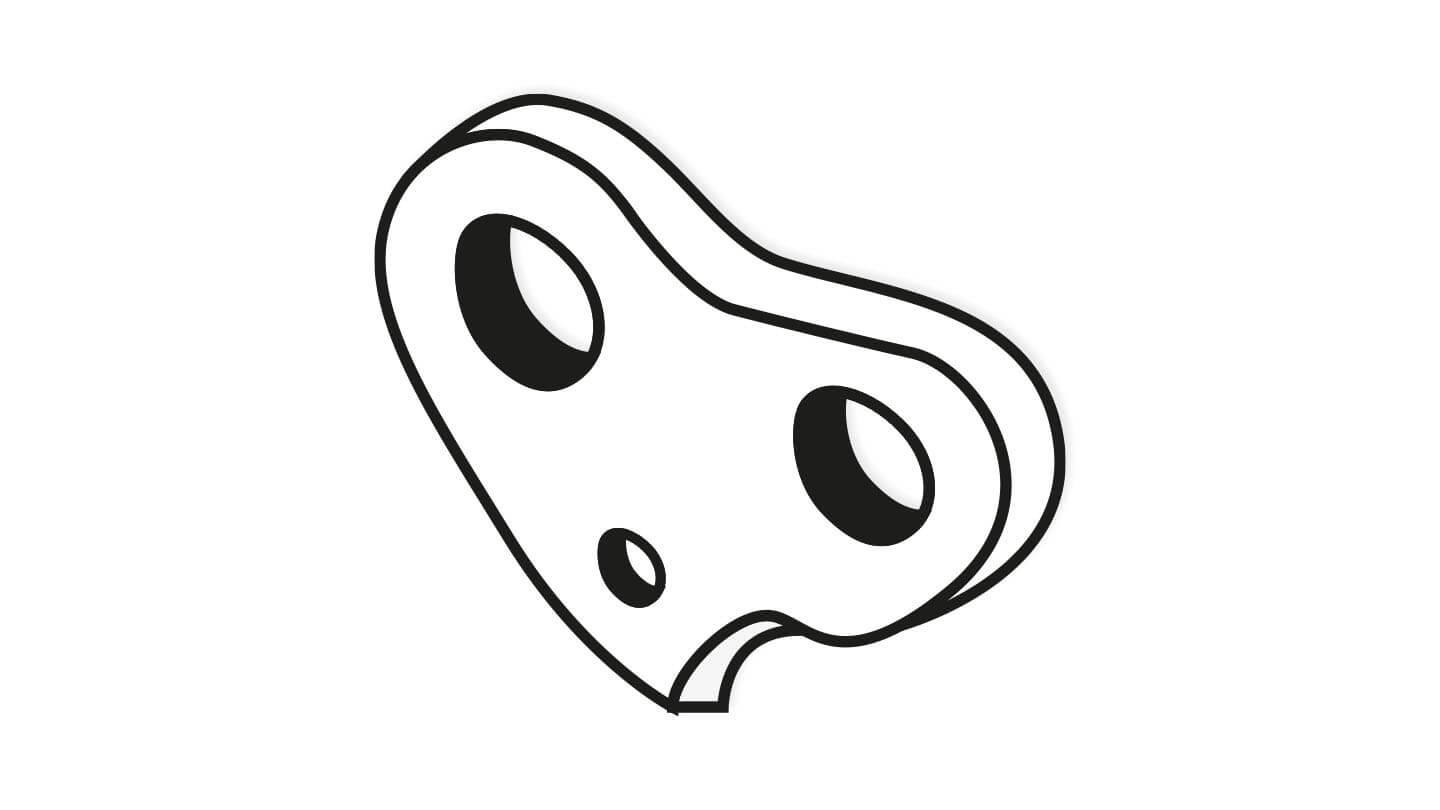

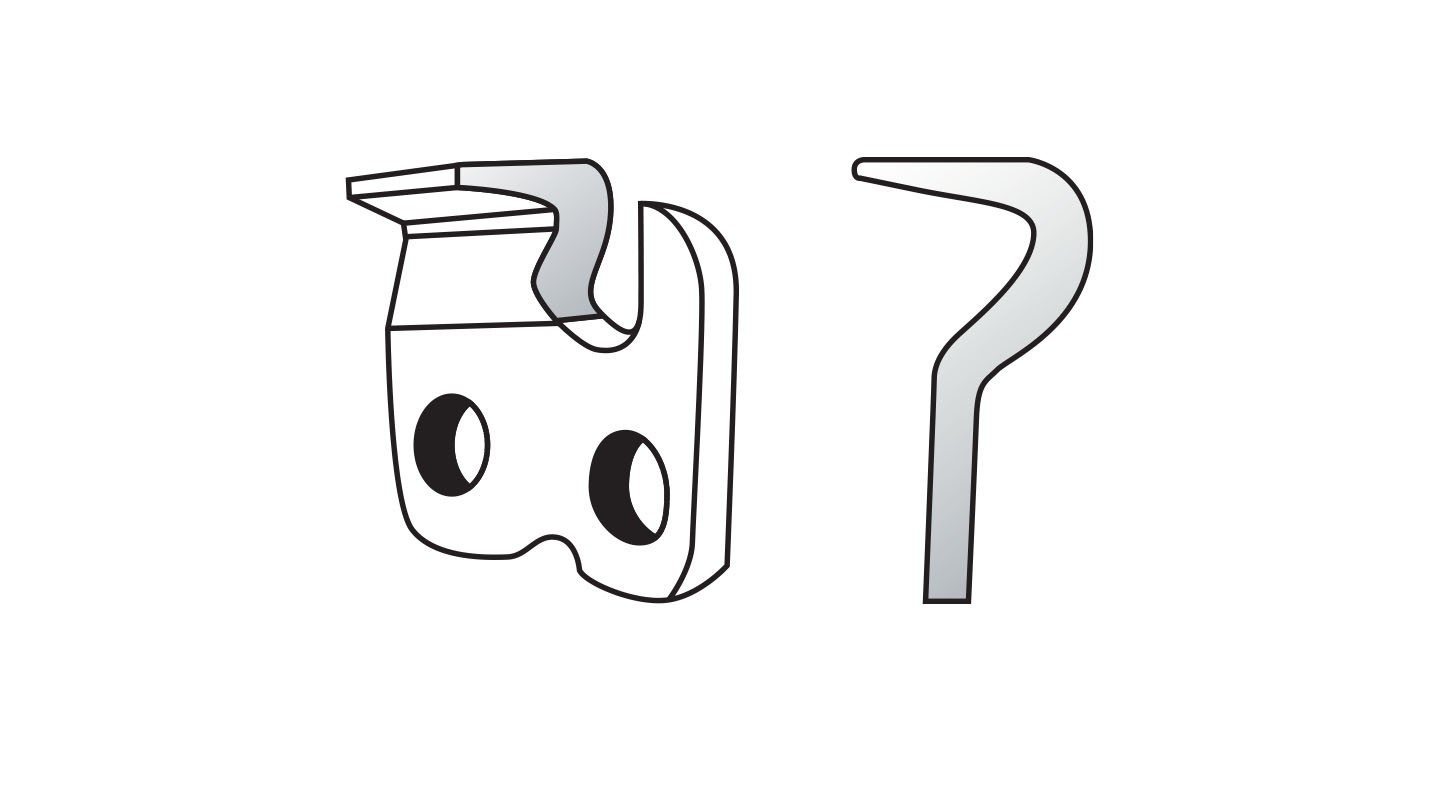

The drive link receives the engine power via the sprocket (chain sprocket) and causes the saw chain to move forwards. The drive links are guided in the guide bar, ensure directional stability and guarantee even distribution of the chain oil as a lubricant. The thickness of the drive links differs depending on the chain type and manufacturer.

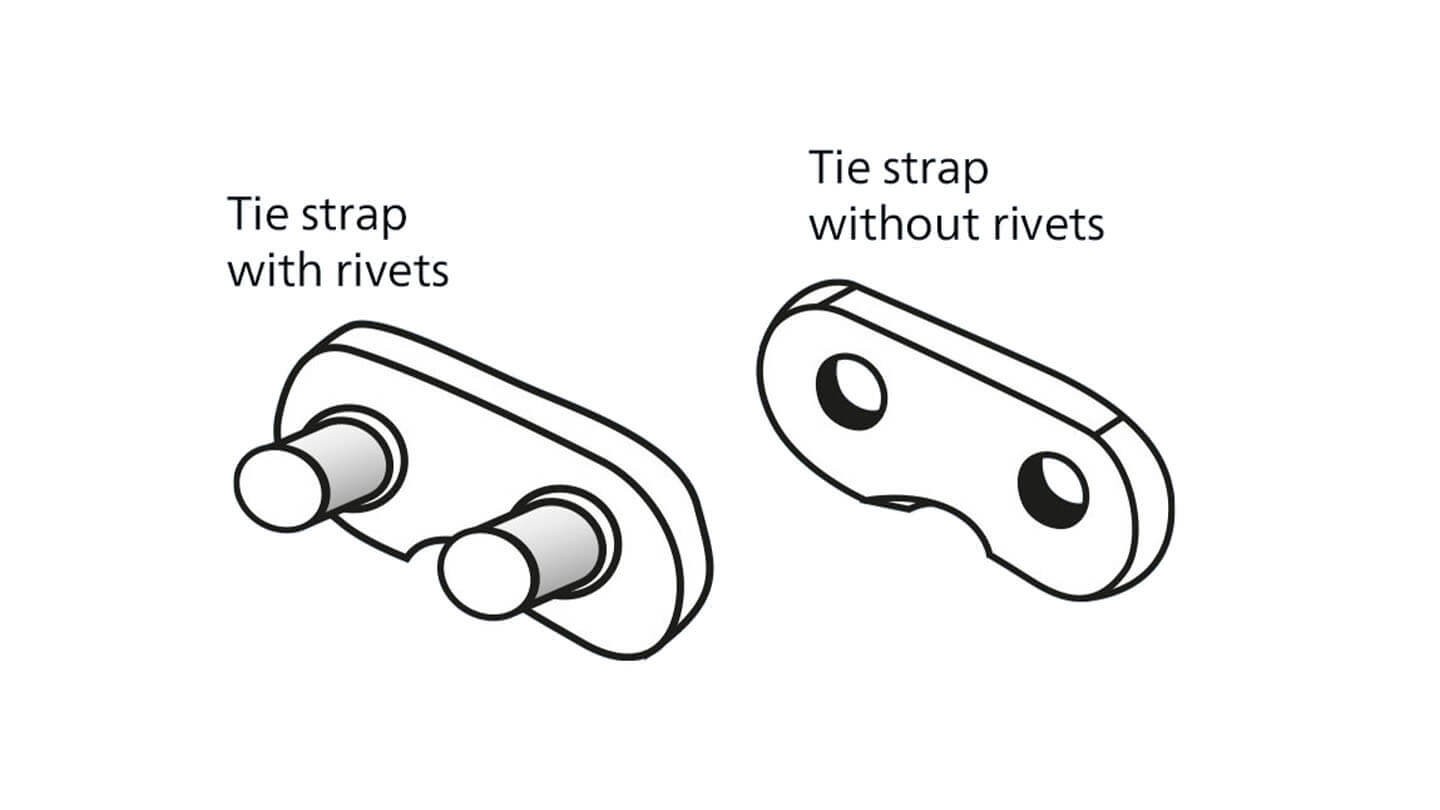

The tie strap consists of two parts and links the drive link and cutting link. Special rivets ensure the joint can move.

How does a saw chain work?

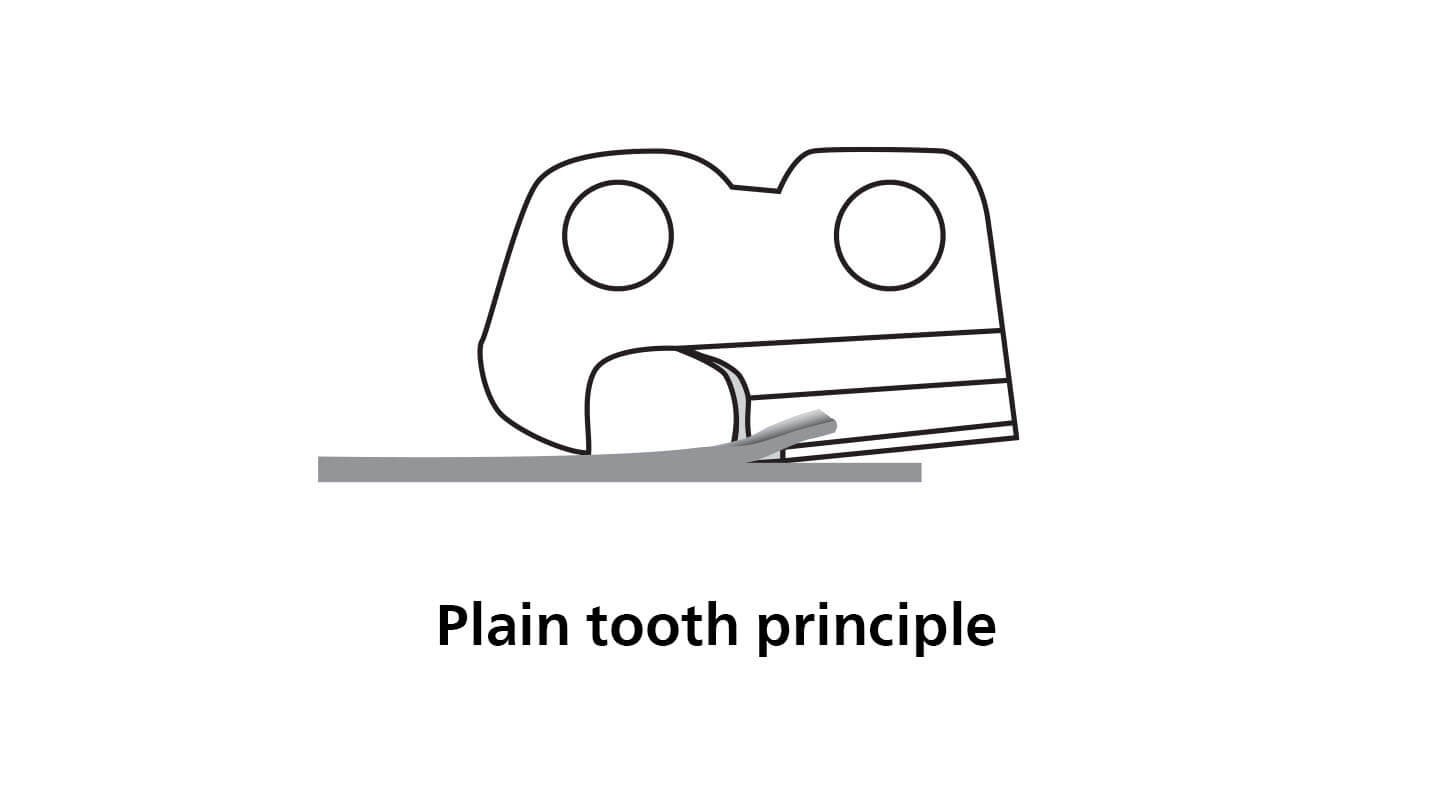

The saw chain on a chain saw works in line with the plane tooth principle. The chips are literally "planed out" of the material.

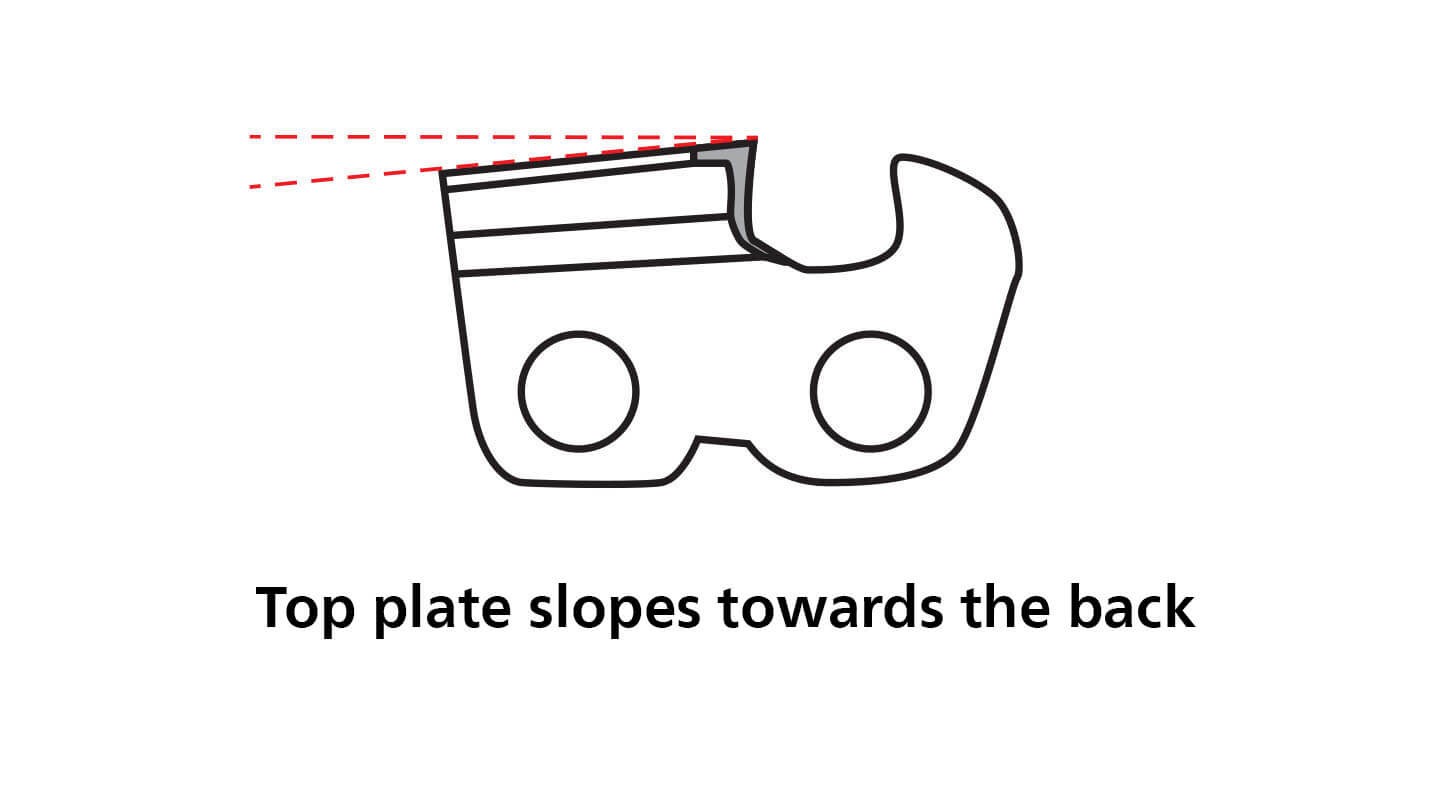

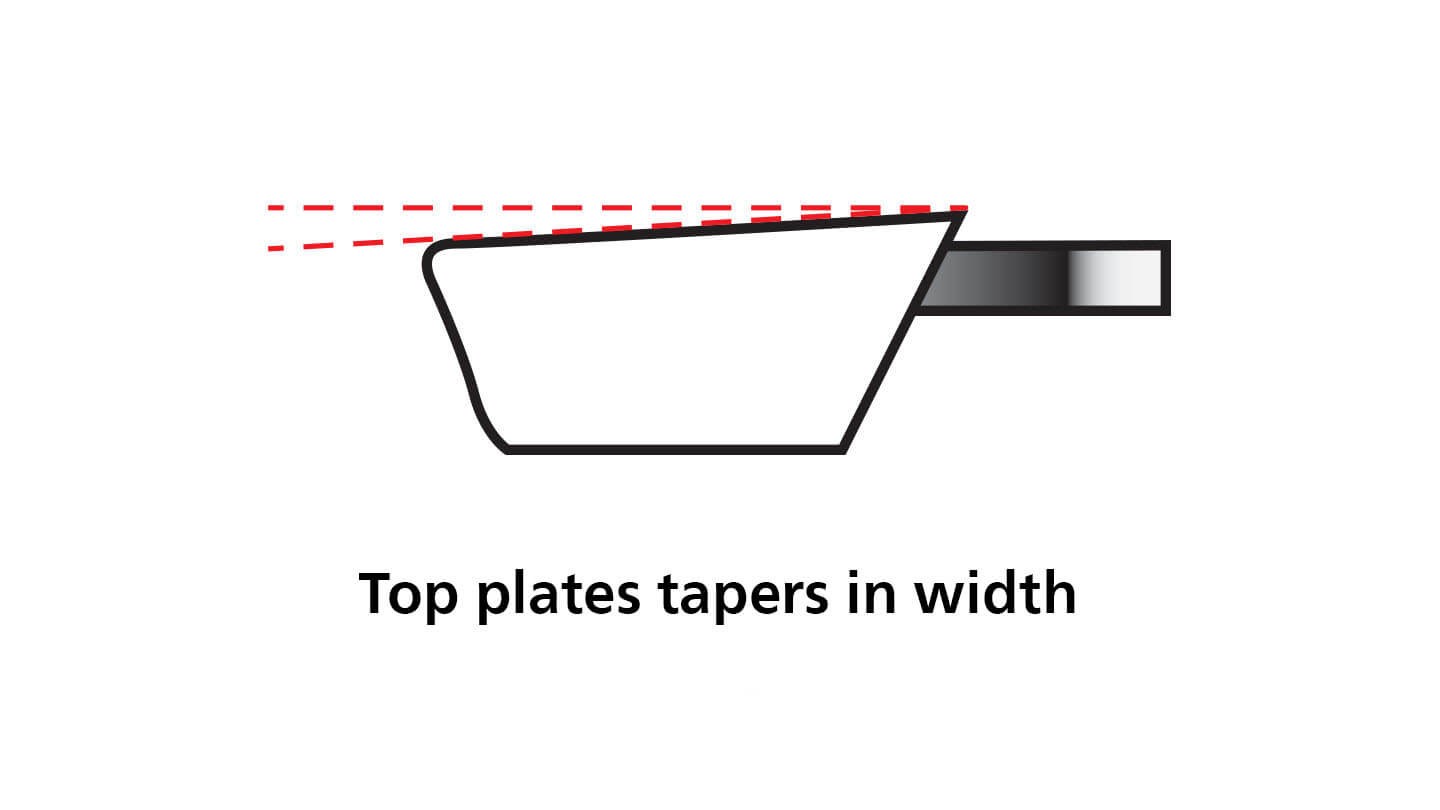

Left and right cutting teeth are arranged in the running direction of the chain. Due to its geometry and the so-called clearance angle (the top plate drops towards the rear and tapers in its width), the cutting tooth works into the material itself. This also happens due to the weight of the chain saw and cutting set, as well as the forwards motion of the saw chain.

As the clearance angle prevents full surface contact with the wood, the saw chain cannot become stuck during the cutting process.

The depth gauge is located in front of the cutting tooth and limits how deep it can penetrate into the wood.

How do you distinguish the tooth shapes?

The different tooth shapes differ as regards the arrangement of the side plate edge and the cutting corner. The tooth shape can best be determined by looking from behind in the running direction of the chain.

Correct sharpening is only guaranteed when you have determined the tooth shape and adhered to the applicable angles.

What tooth shapes are there?

The two most common tooth shapes are the semi-chisel tooth and the full-chisel tooth.

The semi-chisel tooth can be recognized from the rounded corner between the side plate edge and the cutting corner. In comparison to the full-chisel tooth it is less susceptible to damage from dirt and is easier to resharpen. Saw chains with this tooth shape are predominantly used in semi-professional settings.

With the full-chisel tooth the side plate edge and the cutting corner form a square corner. Compared to the semi-chisel tooth, it has lower cutting resistance, contributing to improved cutting performance. This makes it very popular with professionals. It takes practice to sharpen the full-chisel tooth and the process must be performed very precisely.