Ceramic oxide grain CO-COOL abrasive

The abrasive for maximum stock removal

Ceramic oxide grain is a state-of-the-art abrasive with self-sharpening qualities and thus guarantees aggressive grinding with maximum stock removal on hard materials which do not conduct heat well. In addition, the active grinding additives in the coating achieve a significantly higher stock removal rate, prevent clogging and result in cooler grinding.

These characteristics help especially when working on stainless steel (INOX), high-alloy steels, titanium, nickel-based and cobalt-based alloys and extremely hard workpiece surfaces.

Here you will find out more about the advantages of this pointed and sharp-edged grain.

The state-of-the-art abrasive with self-sharpening qualities

Ceramic oxide grain is a state-of-the-art abrasive which is used in a variety of areas due to its toughness, grain structure and its resulting self-sharpening qualities. The pointed and sharp-edged grain offers advantages for use on grinding tools and is suitable for aggressive grinding with maximum stock removal rate on hard materials which do not conduct heat well.

A constant high level of performance is achieved through the self-sharpening ceramic oxide grain. The CO-COOL ceramic oxide grain has active grinding additives in the coating which achieve a significantly higher stock removal rate, prevent clogging and result in cooler grinding.

Due to the special structure of the ceramic oxide grain and the active grinding binding components, the abrasive is outstanding for work on stainless steel (INOX), high-alloy steels, titanium, nickel-based and cobalt-based alloys and extremely hard workpiece surfaces.

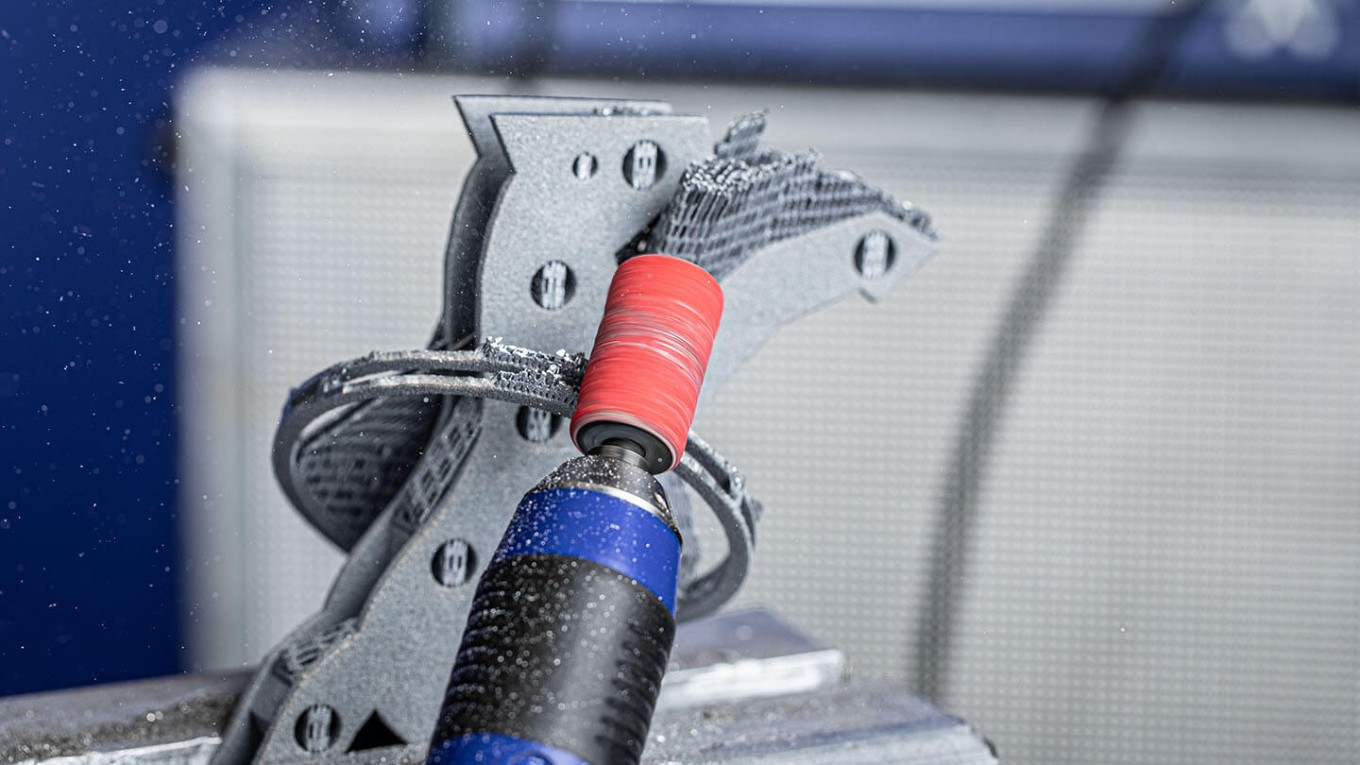

A selection of PFERD tools with the ceramic oxide grain CO-COOL abrasive:

The advantages of tools with ceramic oxide grain CO-COOL abrasive at a glance:

- State-of-the-art abrasive with self-sharpening qualities.

- Aggressive grinding with maximum stock removal rate on hard materials which do not conduct heat well.

- Active grinding additives in the coating prevent clogging and result in cooler grinding.

Which PFERD tools are available with ceramic oxide grain CO-COOL abrasive?

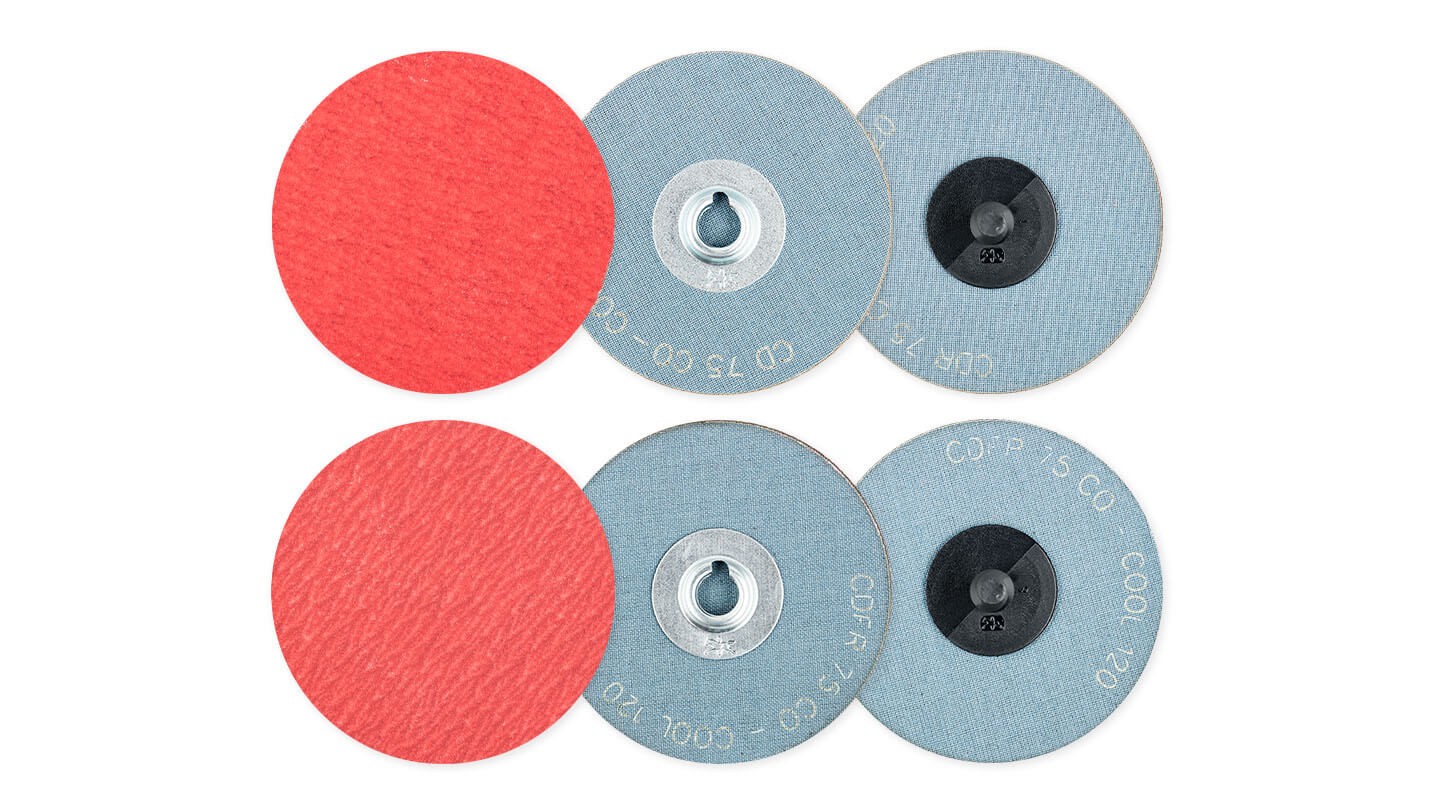

COMBICLICK fibre discs

COMBICLICK fibre discs are ideally suited for coarse grinding work and step-by-step fine grinding.

The CONTOUR type is very flexible and adaptable on account of the outer contour. Cutting into the workpiece is avoided.

Matching backing pads are available.

Fibre discs

Fibre discs impress with their optimum adaptation to contours thanks to their high flexibility. They are ideally suited for coarse grinding work and step-by-step fine grinding.

Matching backing pads are available.

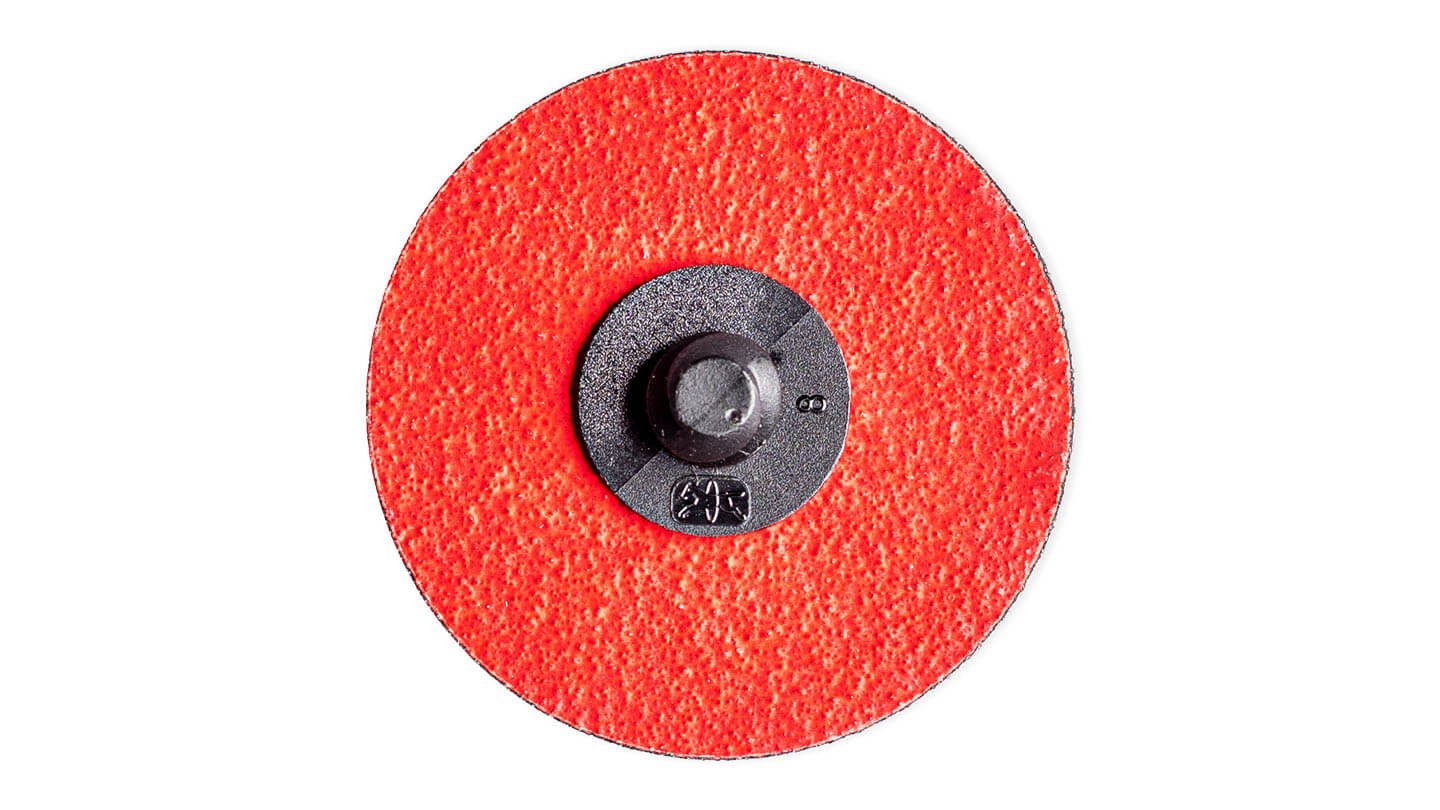

COMBIDISC abrasive discs

COMBIDISC abrasive discs impress with a high profitability thanks to quick tool changes. Their use is particularly comfortable due to simple handling and low-vibration work.

CD, CDR type: Ideally suited for coarse machining and step-by-step fine grinding.

CDF, CDFR type: Exceptionally well-suited to surface and edge grinding. The fibre backing strengthens the abrasive disc and improves stock removal.

The COMBIDISC product range contains a wide selection of midget fibre discs with ceramic oxide grain CO-COOL abrasive for coarse machining and step-by-step fine grinding.

RS type: Outstandingly well suited for weld dressing of backwards repair welds, e.g. in cases, slots and grooves on engines and for processing welded-on combustor plates. Unlike on conventional abrasive discs, the abrasive coating is on the underside of the tool, which allows backwards working.

Matching abrasive disc holders are available.

Schleifbänder

Short and long belts

The range of short and long belts is tailored to the belt grinders that are commonly found on the market and offers the optimum tool for coarse grinding work and step-by-step fine grinding.

Belts for pneumatic drums

The range of abrasive spiral bands for pneumatic grinding drums offer the best tool solution for a lot of applications. Suitable for coarse to fine grinding.

Matching pneumatic drums are available.

Abrasive spiral bands

Abrasive spiral bands are the best tool solution for every application, from fine grinding through to aggressive grinding. They impress with outstanding tool life thanks to a special manufacturting process – even under the toughest work conditions.

Matching rubber drum holders are available.

POLIROLL catridge rolls

POLIROLL tools are suited for work in hard-to-access places. They consist of spirally wound, coated abrasives. The abrasive grain is embedded in the resinoid coating on the sturdy backing material, which achieves the best possible abrasive performance.

POLICAP abrasive caps

POLICAP tools have a seamless design, and the entire tool surface can be used. POLICAP abrasive caps ceramic oxide grain CO-COOL type are offered in cylindrical shape with radius end WRC (previously shape C) and in conical shape with radius end KEL (previously shape L). They impress with high standards of shape accuracy and excellent find grinding thanks to a special manufacturing process.

Matching abrasive cap holders are available.

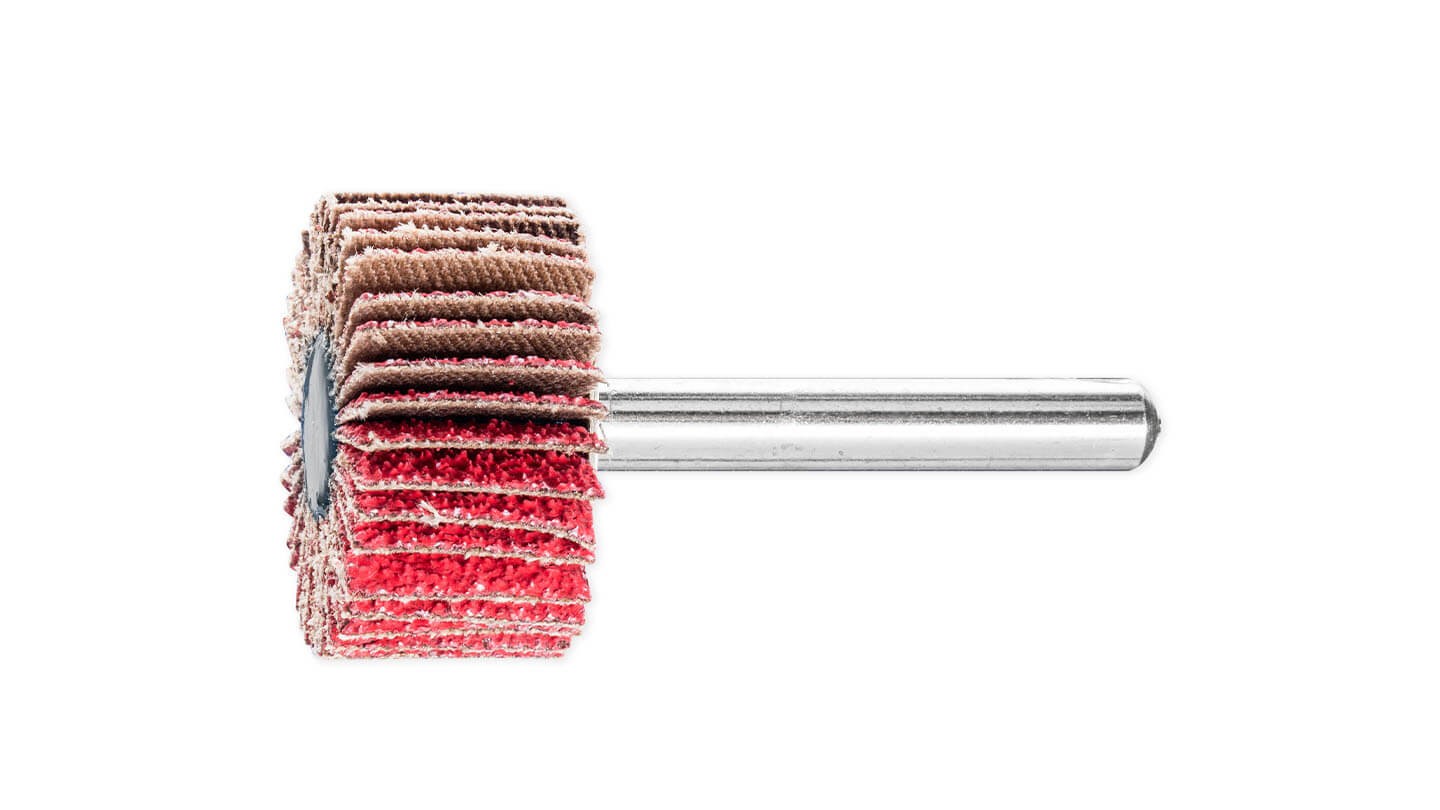

Mounted flap wheels

On mounted flap wheels, the flaps made of coated abrasive are arranged radially around the tool axis in a fan-type structure. Their flexibility enables them to adapt perfectly to the contours of the workpiece. The abrasive grain is embedded in the sturdy, flexible cloth backing material by means of a resinoid bond.

Mounted flap wheels impress with a consistently high stock removal throughout the entire tool life as new, aggressive abrasive material is constantly freed up. Face-down use very close to edges and in corners is possible thanks to the flat, moulded-core design.

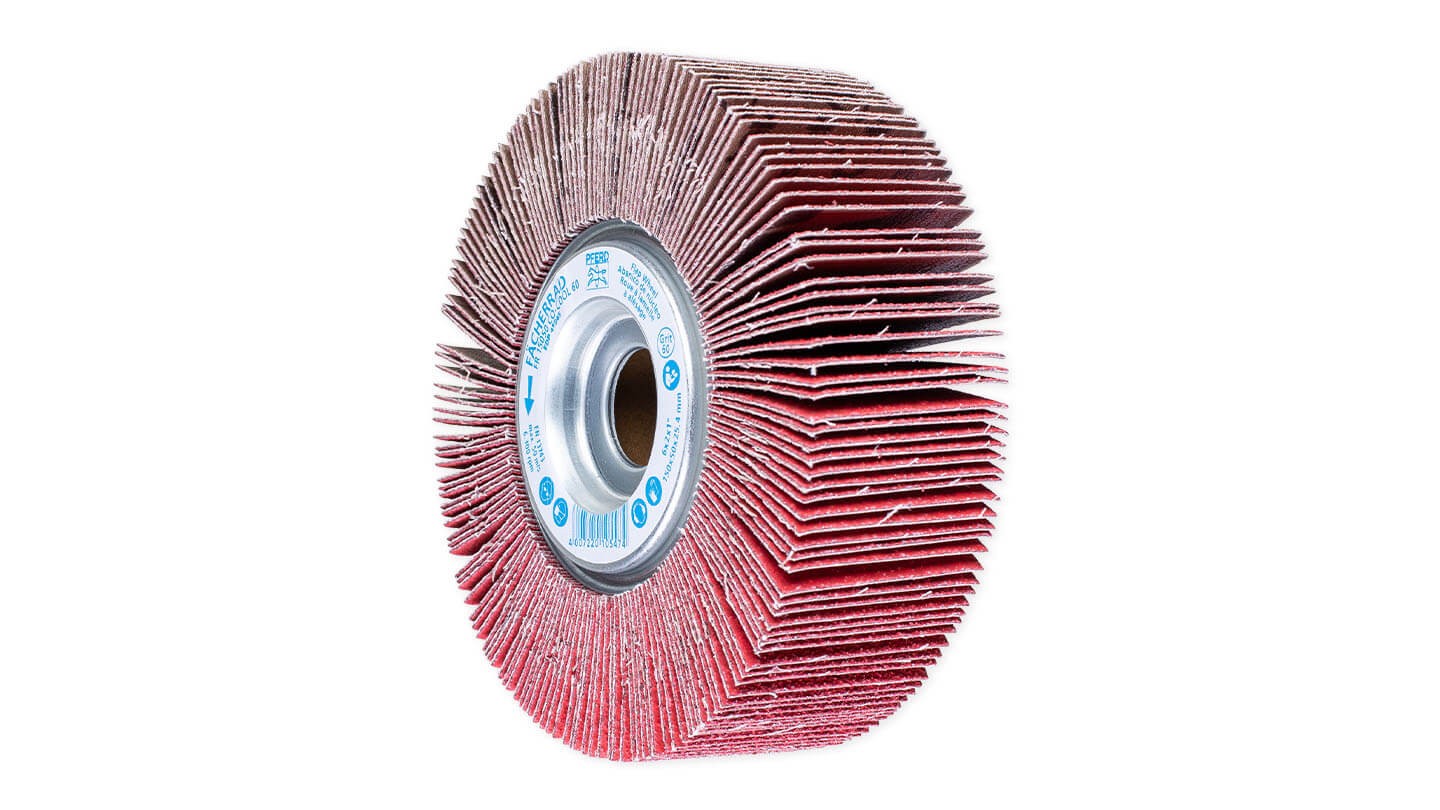

Unmounted flap wheels

On unmounted flap wheels, the flaps made of coated abrasive are arranged radially around the tool axis in a fan-type structure. Their flexibility enables them to adapt perfectly to the contours of the workpiece. The abrasive grain is embedded in the sturdy, flexible cloth backing material by means of a resinoid bond.

Unmounted flap wheels impress with a consistently high stock removal throughout the entire tool life as new, aggressive abrasive material is constantly freed up. Face-down use very close to edges and in corners is possible thanks to the flat, moulded-core design.

Matching arbors are available.

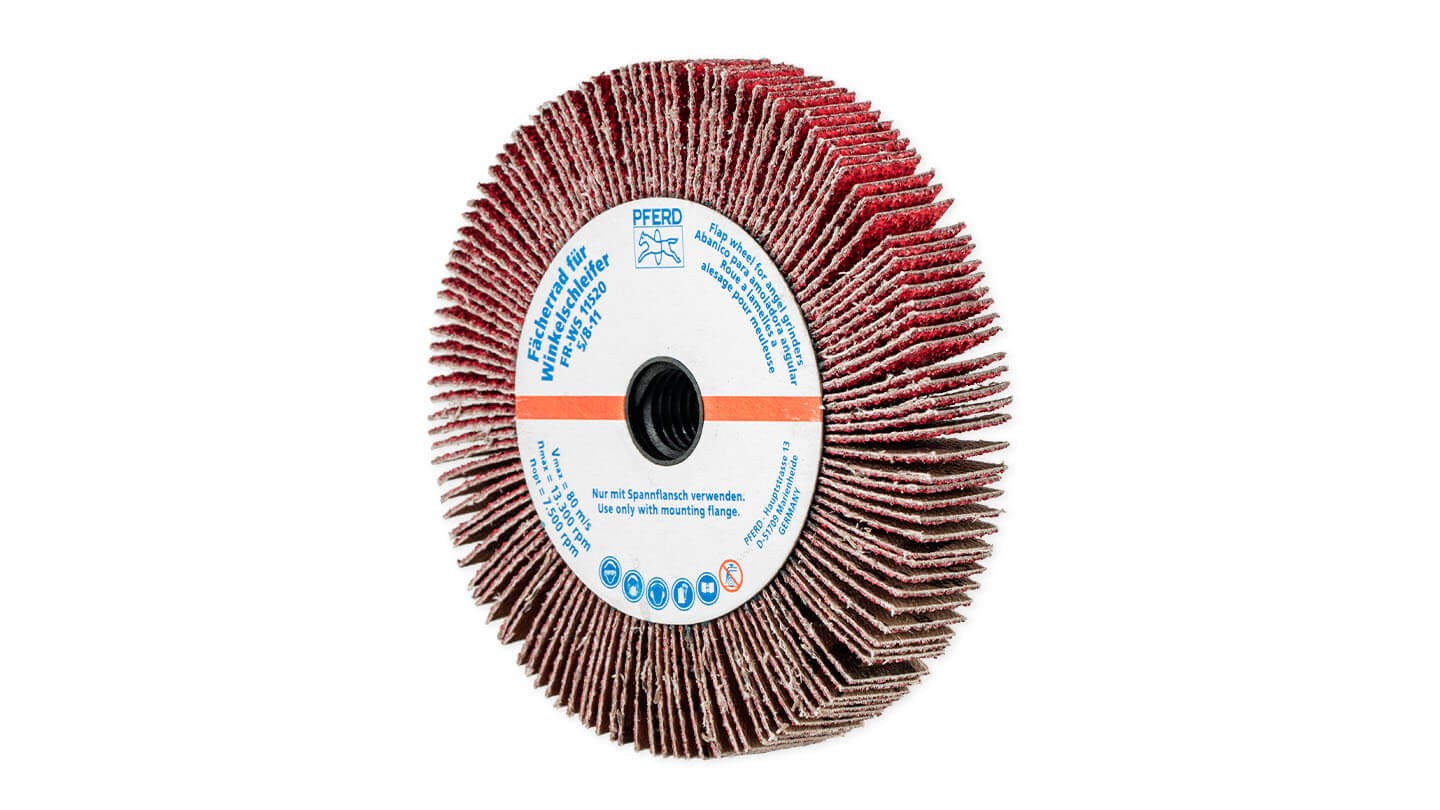

Unmounted flap wheels for angle grinders

On unmounted flap wheels, the flaps made of coated abrasive are arranged radially around the tool axis in a fan-type structure. Their flexibility enables them to adapt perfectly to the contours of the workpiece. The abrasive grain is embedded in the sturdy, flexible cloth backing material by means of a resinoid bond.

The ideal tool for use on angle grinders in assembly shop operations. It can be mounted directly on the angle grinder without additional clamping devices.

POLIVLIES grinding dics

POLIVLIES grinding discs are particularly suited to work on large surfaces made from stainless steel (INOX). They create a consistently high surface quality throughout the entire tool life as new, sharp abrasive material is constantly freed up.

POLIFAN flap discs

POLIFAN flap discs impress with particularly cool grinding on materials that are difficult to machine such as high-alloy and rust-resistant steel, nickel-based alloys or titanium alloys.

Performance Line SG tools achieve optimum results with maximum economic efficiency.