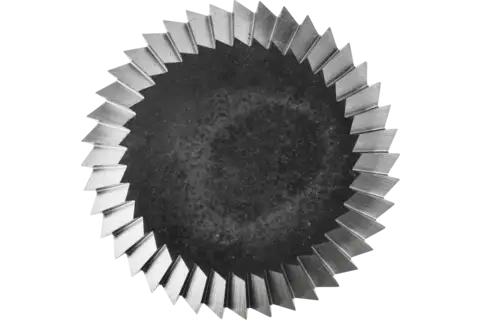

Tungsten carbide burrs for general use, cut 3, rim shape N

Tungsten carbide burr rim shape N dia. 25x06 mm shank dia. 8 mm Z3 universal medium

Technical information

Tungsten carbide burr rim shape N dia. 25x06 mm shank dia. 8 mm Z3 universal medium

- Angle

- 90 °

- Cut

- 3

- Dia. external

- 25 mm

- Dia. shank

- 8 mm

- Length, cut

- 6 mm

- Length, total

- 1,811

- Length, total

- 46 mm

- RPM from, grey cast iron, white cast iron

- 6000 RPM

- RPM from, hard non-ferrous metals

- 3000 RPM

- RPM from, hardened, heat-treated steels over 1,200 N/mm²

- 3000 RPM

- RPM from, rust and acid-resistant steels

- 3000 RPM

- RPM from, soft non-ferrous metals

- 6000 RPM

- RPM to, grey cast iron, white cast iron

- 8000 RPM

- RPM to, hard non-ferrous metals

- 4000 RPM

- RPM to, hardened, heat-treated steels over 1,200 N/mm²

- 4000 RPM

- RPM to, rust and acid-resistant steels

- 4000 RPM

- RPM to, soft non-ferrous metals

- 8000 RPM

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

- Materials that can be worked

- Applications

- Drive types