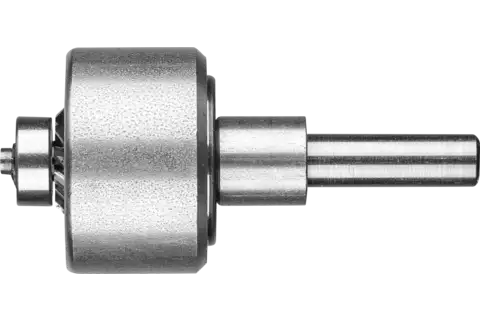

Tungsten carbide burrs for high performance, EDGE, conical counterbore shape KSK EDGE,

Tungsten carbide burr EDGE ALU conical KSK 45 ° ECS dia. 16x03 mm shank dia. 6 mm work on edges aluminium

Matching accessories & spare parts

Technical information

Tungsten carbide burr EDGE ALU conical KSK 45 ° ECS dia. 16x03 mm shank dia. 6 mm work on edges aluminium

- Angle

- 90 °

- Cut

- EDGE ALU

- Dia. ball bearing

- 10 mm

- Dia. external

- 16 mm

- Dia. shank

- 6 mm

- Dia. sleeve

- 25 mm

- Length, construction

- 24 mm

- Length, cut

- 1 mm

- Length, total

- 2,047

- Length, total

- 52 mm

- RPM from, hard non-ferrous metals

- 12000 RPM

- RPM from, soft non-ferrous metals

- 18000 RPM

- RPM from, thermoplastics, fibre-reinforced plastics (GRP/CRP)

- 12000 RPM

- RPM to, hard non-ferrous metals

- 22000 RPM

- RPM to, soft non-ferrous metals

- 22000 RPM

- RPM to, thermoplastics, fibre-reinforced plastics (GRP/CRP)

- 22000 RPM

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

Ordering notes

- Materials that can be worked

- Applications

- Drive types

PFERDVALUE

PFERDEFFICIENCY

recommends burrs with the EDGE cut for working for long periods with low levels of fatigue, whilst saving resources and achieving perfect results as quickly as possible.